The demand for an article of instruction on saw filing having been demonstrated to us not only by personal inquiry and letter, but also by the return of fine quality saws, pronounced defective through a lack of knowledge of how to keep them in order, or by the use of extensively advertised so-called saw sets and other tools, which pull the saw blade apart or so distort it as to render it unfit for use-has led us to compile this book for gratuitous distribution for the enlightenment of the amateur and the improvement of the expert mechanic.

We will endeavor to give, in the following pages, such practical information as to the proper methods of keeping saws in order and of the tools with which to do so, that will overcome the above mentioned pit-falls to the proper working of the saw. We offer our wide experience and the reputation of our goods for the efficiency of this treatise, which has been gleaned from the most scientific saw makers and most practical saw filers in the world. While we admit there are other methods of putting saws in order, we claim our modes to be the easiest and equally or more effective.

We take occasion to thank our patrons for their appreciation of our products. The High Standard, which is the basis of our constantly increasing business, shall be maintained, and we trust thereby to retain their good will and increase our trade in future.

The following cuts are full size of the respective number of teeth and points per inch which they represent. It will be noticed that in one inch space there is one tooth less than there are points. Order all saws by the number of "POINTS" to the inch measuring from point to point of teeth.

Rip saw teeth are graduated from butt to point of blade, the narrow end being one point to the inch finer than at butt; the "POINTS" being measured at butt of blade.

PRINCIPLE OF CONSTRUCTION

The saw is either reciprocating or continuous in action, the first being a flat blade and practically straight edge, making a plane cut, as from in hand, mill, jig and sash saws; the latter, either a circular or rotating disc, cutting in a plane at a right angle to its axis, a cylindrical or barrel shape with a convex edge cutting parallel to its axis, or a continuous ribbon or band running on two pulleys making a plain or curved cut with a straight edge parallel to their axis of rotation.

Practically speaking, the teeth are a series of knives set on a circular or straight line, each tooth cutting out its proportion of wood and prevented from cutting more by the teeth on either side of it. Each tooth should cut the same amount and carry out the chip or dust, dropping it below the material being sawed. Different kinds of wood require teeth varying in number, angle or pitch and style of filing.

The perfection of a saw is one that cuts the fastest and smoothest with the least expenditure of power; to do this, it is evident that each tooth should be constructed and dressed as to do an equal proportion of the work, for if any of the teeth are out of line or shape, they are not only useless themselves, but a disadvantage to the others. We find many good mechanics who frankly acknowledge that they never could file a saw satisfactorily; the probable reason is that they never studied the principle of the action or working of the tool. There is no reason why any man of ordinary mechanical ability should not be able to file, and keep his saw in order, but like all trades, it requires practice and study of the subject.

The following illustrations and explanations will greatly assist in the selection of a saw and show the best method of keeping it in proper working order. These should be carefully studied.

A saw tooth has two functions-paring and scraping. A slitting or ripping saw for wood should have its cutting edge at about right angles to the fibre of the wood, severing it in one place, the throat of tooth wedging out the piece. In a cross-cut wood saw, the cutting edge also strikes the fibre at right angles to its length, but severs it on each side from the main body before dislodging it.

LAYING-OUT TEETH.

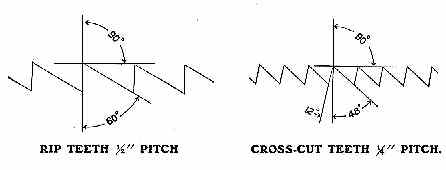

The following cuts show the method of laying-out Rip saw teeth and Cross-cut saw teeth, the angles for the teeth remaining the same as in these sketches for all sizes of teeth. It will be noted that the Rip saw tooth is made with a straight front, whilst the front of the Crosscut tooth is given a slight pitch or rake.

Rip Saws

Fig. 1 is a four-point rip or slitting saw with the rake all in front, where the cutting duty is. This saw should be filed square across, filing one-half the teeth from each side after setting, which will give a slight bevel to the cutting edge of tooth, as it should be for soft wood; for medium hard woods a finer toothed saw with five points to the inch should be used and dressed in the same manner; for the very hardest and toughest cross-grained woods a still finer toothed saw is required, with the teeth filed slightly beveling, as ripping cross-grained stuff partakes a little of the nature of cross-cutting.

In all cases where ripping is done, the thrust of the saw should be on an angle of about 45 degrees to the material being cut, as shown in Fig. 2, this makes a shearing cut, an advantage that can be quickly demonstrated with an ordinary pocket knife cutting any piece of wood. For ripping thoroughly dry lumber, it will be found advantageous to use an extra thin back saw which will run without set.

CROSS-CUT HAND SAWS

In cross-cutting the fibre of the wood is severed twice-on each side of the saw-the thrust dislodging and carrying the dust out. Fig. 3 is a five-point peg tooth cross-cut saw with the rake on the soft wood side. For the same reason that the rip saw has the rake on front of the tooth, the cross-cut has it on the side, as that is where the cutting duty is. The bevel or fleam to teeth in Fig. 3 is about 45 degrees, while there is no pitch at all; the angle on each side being the same, forms the "peg tooth," which is best adapted to cutting soft, wet and fibrous woods. This style of tooth is principally used in Buck-saws.

In cross-cutting the fibre of the wood is severed twice-on each side of the saw-the thrust dislodging and carrying the dust out. Fig. 3 is a five-point peg tooth cross-cut saw with the rake on the soft wood side. For the same reason that the rip saw has the rake on front of the tooth, the cross-cut has it on the side, as that is where the cutting duty is. The bevel or fleam to teeth in Fig. 3 is about 45 degrees, while there is no pitch at all; the angle on each side being the same, forms the "peg tooth," which is best adapted to cutting soft, wet and fibrous woods. This style of tooth is principally used in Buck-saws.

In all cases, the size and length of teeth depend largely upon the duty required; a long tooth has the demerit of being weak and liable to spring, but the merit of giving a greater clearance to the saw-dust. The throat space in front of each tooth must be large enough to contain the dust of that tooth from one stroke; the greater the feed, the deeper the dust chamber required, or, more teeth.

The first point to be observed in the selection of a saw is to see that it "hangs" right. Grasp it by the handle and hold it in position for working, to see if the handle fits the hand properly. These are points of great importance for comfort and utility. A handle should be symmetrical, and the lines as perfect as any drawing. Many handles are made of green wood; they soon shrink and become loose, the screws standing above the wood. We season our handle-wood three years before using. An unseasoned handle is liable to warp and throw the saw out of shape. The next thing in order is to try the blade by springing it, seeing that it bends regularly and evenly from point to butt in proportion as the width and gauge of the saw varies. If the blade is too heavy in comparison to the teeth, the saw will never give satisfaction, because it will require more labor to use it; the thinner you can get a stiff saw the better; it makes less kerf and takes less muscle to drive it. This principle applies to the well-ground saw. There is less friction on a narrow true saw than on a wide one; you will get a smaller portion of blade, but you will save much unnecessary labor at a very little loss of the width.

See that it is well set and sharpened and has a good crowning breast; place it at a distance from you and get a proper light on it, by which you can see if there is any imperfection in grinding or hammering. We should invariably make a cut before purchasing a saw, even if we had to carry a board to the hardware store. We set our saws on a stake or small anvil with a hammer; a highly tempered saw takes several blows, as it is apt to break by attempting to set it with but one blow. This is a severe test, and no tooth ought to break afterwards in setting, nor will it, if the mechanic adopts the proper method, The saw that is easily filed and set is easily made dull. We have frequent complaints about hard saws, though they are not as hard as we would make them if we dared; but we shall never be able to introduce a harder saw until the mechanic is educated to a more correct method of setting it. As a rule, saws are given more set than is necessary, and if more attention was paid to keeping points of teeth well sharpened, any well-made saw would run with very little set, and there would be fewer broken ones. The principal trouble is that too many try to get part of the set out of the body of the plate, whereas the whole of the set should be on the teeth. Setting below the root of the tooth distorts and strains the saw-plate, which may cause a full-tempered cast-steel blade to crack and eventually break at this spot; and it is always an injury to the saw, even if it does not crack or break.

The teeth of a hand saw should be filed so true, that on holding it up to the eye and looking along its edge, it will show a central groove down which a fine needle will slide freely the entire length; this groove must be angular in shape and equal on each side, or the saw is not filed properly and will not run true.

Fig. 4 shows how the groove should appear on looking down the edge of the saw; the action should be such that the bottom of kerf will present the appearance as shown in Fig. 5, and not like Fig. 6; the cutting action is as shown in Fig. 7, the cutting being done with the outside of tooth, the fibre of the wood is severed in the two places and the wood is crumbled out from point to point by the thrust of the saw.

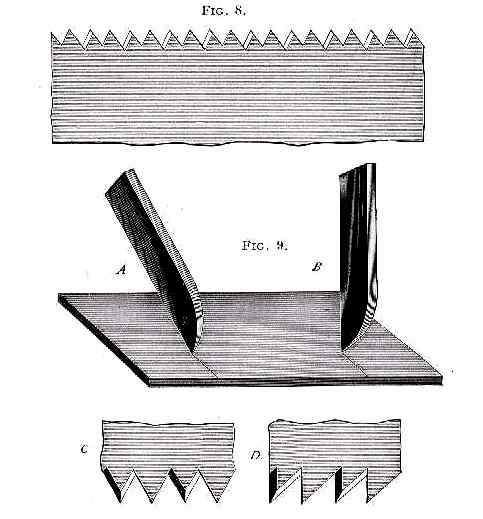

Fig. 8 shows a six-point cross-cut saw filed with a medium amount of bevel on front or face of tooth, and none on the back. This tooth is used in buck-saws, on hard wood, and for general sawing of woods of varying degrees of tenacity. This style of dressing is the best, but a number of saws each having teeth suited to its particular work, will be found more advantageous than trying to make one saw serve for all kinds of hand saw work.

We will now consider the cross-cut saw tooth, in regard to rake or pitch; this being one of the most important features, too much care cannot be taken to have the correct amount of pitch for the duty required. To illustrate this, Fig. 9 represents a board, across which we wish to make a deep mark or score with the point of a knife; suppose we hold the knife nearly perpendicular as at B, it is evident it will push harder and will not cut as smoothly as if it was inclined forward as at A; it follows then that the cutting edge of a cross-cut saw should incline forward as at C, rather than stand perpendicular as at D.

Too much hook or pitch, and too heavy a set are very common faults, not only detrimental to good work but ruinous to the saw; the first by having a large amount of pitch, the saw takes hold so keenly that frequently it "hangs up" suddenly in the thrust-the result, a kinked or broken blade; the second, by having too much set, the strain caused by the additional and unnecessary amount of set is out of proportion to the strength of the blade, and is broken in the same manner. The most general amount of pitch used is 60 degrees, though this may be varied a little more or less to advantage, as occasion may demand.

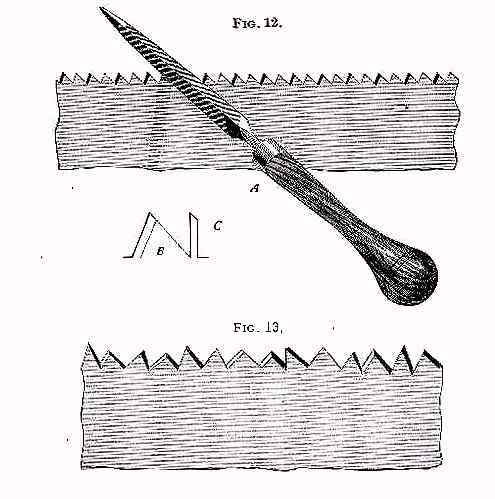

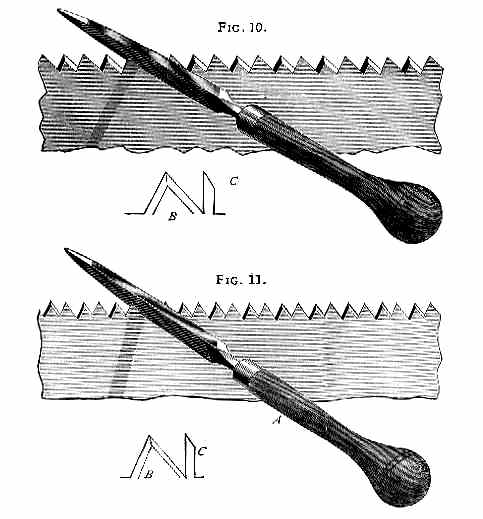

The next point to he considered is the bevel, or fleam, of the point. In Figs. 10, 11 and 12, the filer, as in all cases, files from the heel to the point, which is the only correct way. The file is supposed to be horizontal to the perpendicular of the side of saw, and on an angle of about 45 degrees longitudinally with the length, measuring from file line toward heel.

Fig. 10 is a five-and-a-half-point cross-cut saw showing the same amount of fleam front and back, this saw is best suited for work in soft wood, and where rapid, rather than fine work is required. A shows the position of the file, B an exaggerated view of shape of point, and C the shape of point.

Fig. 11 is a seven-point saw for medium hard woods, illustrated in same manner as Fig. 10. This tooth has less fleam on the back, which gives a shorter bevel to point, as at C.

Fig. 12 is a still finer saw, having ten points to the inch. This saw has no fleam on back, the result being very noticeable at C and B. This style of point is for hard wood.

It will be seen that the bevel on the front of teeth in Figs. 10, 11 and 12 is the same, but the bevel of the point looking the length of saw is quite different, consequent upon the difference in the angles of the backs. [see footnote]

Fig. 13 is a representation of some of the saws we have seen; there are entirely too many such now in use, and we have no doubt their owners are shortening their lives in the use of them as well as those of the saws. To owners of such saws we say, take them to the factory and have them retoothed, or buy a new saw and take a fresh start, and steer clear of this style of filing.

As we said in the preceding pages, and as will be seen by Figs. 10, 11 and 12, the filing should be done from the heel of saw toward the point. Many practical saw filers contend this is wrong, that the filing should be done from point of saw toward the handle, but the only support they have for their theory is that they do away with the feather edge that the filing from the heel of saw puts on the cutting face of tooth. The feather edge is no objection, as the main part of it is removed when the teeth are side-dressed after filing. Against the correctness of filing from point to handle may be cited the following objections:

Where a different angle of back is required (it being remembered that angle of face should be the same in nearly all cross-cut hand saws, and that angle of back governs angle of point), it will be found very difficult to obtain it without changing angle of face of tooth, and as the cutting duty is on the long side of face, any change is of course of great influence.

Again, (though we think the above argument sufficient) to file from point of saw, it is necessary to file with the teeth bent toward the operator; this will cause the saw to vibrate or chatter, which not only renders good, clean, even filing impossible, but breaks the teeth off the file.

In the preceding illustrations, we have only given the coarser saws that are in most general use, but the same principle of filing should be applied to the finer toothed saws regarding angles and pitch suitable for woods of different degrees of hardness, the only actual difference being that one saw has finer points, and they being finer, require a little more care and delicate touch in setting and filing.

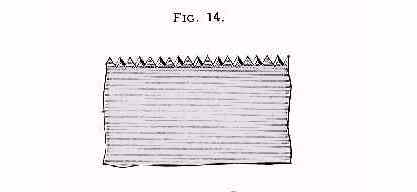

Fig. 14 is a section of an eleven-point saw suitable for the finer kinds of work on dry, soft woods. such as cutting mitres, dove-tailing, pattern work, etc.

Fig. 14 is a section of an eleven-point saw suitable for the finer kinds of work on dry, soft woods. such as cutting mitres, dove-tailing, pattern work, etc.

Fig. 15 shows a section of saw with same number of points as Fig. 14, but filed same as Fig. 12. This saw is for finer work, same as Fig. 14 only on the medium hard woods.

Fig. 16 is a still finer saw for fine work on the very hardest woods having same dress as Fig. 14.

Fig. 17 is the finest toothed saw of its kind that is made for wood. All the above mentioned saws in Figs. 14, 15, 16, and 17, are made especially hard and will not admit of setting, but being made thinner at the back, when properly filed, will cut clean and sweet. Teeth such as shown in Fig. 17 are used principally on Back Saws and smooth cutting hand saws. To maintain the original shape of these teeth use our cant safe back file.

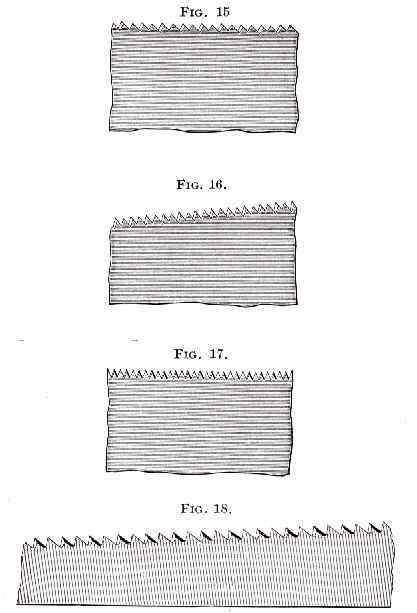

Fig. 18 is a section of a pruning saw which differs from a cross-cut hand saw in being thicker, having a little more pitch to the teeth and being ground thinner on the back in proportion to its width. These, of course, are made for cross-cutting only, as there is not as great a variety in the work, nor as much difference in the woods to be sawed as to degrees of hardness, being used only as a pruning saw on fruit and shade trees, which are always practically green and comparatively soft.

SETTING THE TEETH OF SAWS

This is an important part of the work of keeping a saw in order and should always be done after the teeth are jointed and before filing. In all cases the set should be perfectly uniform, as the good working of the saw depends as much on this as on the filing. Whether the saw is fine or coarse, the depth of set should not go, at the most, lower than half the length of the tooth, as it is certain to spring the body of saw if not break the tooth out. Soft, wet woods require more set as well as coarser teeth than dry, hard woods. For fine work on dry woods, either hard or soft, it is best to have a saw that is ground so thin on the back that it requires no set; such saws are made hard and will not stand setting, and an attempt to do so would surely break the teeth out.

WHAT CONSTITUTES HAND and RIP SAWS?

As a matter of interest it may be stated whilst there is a general understanding in the Hardware Trade that Handsaws are 26 inches long and Rip saws 28 inches long, this is not carried out by facts. There are a great many Rip saws made of shorter lengths, such as 22 and 24 inch, for the term "Rip" applies to shape and style of tooth only and not to the length of the saw. Likewise the Cross-cut or Cutting-off saws may be made in any length desired. As to the graduation of teeth in Rip Saws, the purpose of this is to enable the user to start the saw in the work more easily by commencing the cut with the end or point of blade where the teeth are somewhat finer than those at the butt.

PANEL SAW is a term commonly applied to any Hand Saw with cross-cutting teeth, shorter than 26 inches in length. It was formerly used in designating cross-cutting Hand Saws with fine teeth, of any length, but is now obsolete in that particular.

TENON SAW. Some mechanics apply this term to Panel Saws, though it more properly applies to a Back Saw.

BACK SAW, sometimes termed Tenon Saw, is used for fine bench work, pattern-makers, joiners, etc., and is also made in special lengths and widths for use in mitre-boxes for cutting moulding, etc.

The MITRE-BOX SAW has a peculiar shaped butt or heel, making the toothed edge two inches shorter than the full length of blade. The purpose of this is to prevent the "heel" from catching in the work.

The "Nib" near the end of a handsaw has no practical use whatever, it merely serves to break the straight line of the back of blade and is an ornamentation only.