|

|

Recently I took delivery of two Bad Axe tenon saws. A twelve-point crosscut and an eleven-point rip, both 16" in length. I carefully unpacked them from their well-padded box. The saws are absolutely beautiful to look at, and that's what I did for several minutes. The dark etch against the spotless, shining steel is striking. The handles and hardware look great. The back with the gun-bluing contrasts with the blade in much the same way, but even more, than the etch.

I set up a piece of soft maple on the bench to give the crosscut a try. The handle fits my hand perfectly, no "close-enough" or "I guess that will work," but sits in my 3-finger grip as if it were part of my hand. I took two free-hand cuts, about a half an inch deep, parallel, about an eighth of an inch apart. They went exactly where I wanted them and the depth was the same at the back of the cut as the front both times. Two for two with the cross cut. The rip saw cut a straight line in the same scrap of maple, a stick about two inches wide and 6/4" thick. Later I laid out a tenon with my marking gauge on a stick of mahogany, a little under two inches wide and one inch thick. I used the crosscut to cut the shoulders. The saw starts easily, but has an aggressive cut, requiring a light hand to push the saw and letting the saw do its work, which goes quickly. I reposition the stick and take out the rip saw. The cuts go smoothly, start without a lot of effort, follow my line, and the out-cut ends right where I think it should be. These saws have no "getting used to." They work easily, predictably, and efficiently. One of the features of the Bad Axe saw that I like is the traditional, folded steel back with bluing. There have been a number of dovetail and tenon saws on the market for the last dozen years with brass backs, milled with a slot to receive the blade and is fastened to the saw. The argument for that method is it doesn't move and warp the saw plate if the saw is dropped. Same would be true if you threw the saw against the wall. I don't recommend you do that, either. The real problem with dropping a saw is you break the handle, which is not as easily fixed. Find a place other than your work surface to place your tools when you're not using them. The slotted back is a recent development. If you went to a machinist and said you wanted to make saw backs, he'd probably say the slot is the only way to go. But he wouldn't be a saw guy. How can folding a steel back be a bad idea if it was the only way that part was made for at least 150 years? If it were better to use a slotted back, then Disston would have done it. He improved every part of the saw except the back. The saw screws and the medallion or label screw are milled brass. This is also an improvement over split nut or spanner screws on saws, which are hard to adjust without damage. The cherry handle is a fine choice of wood species. It has good strength, density, and holds the finely-shaped details of the handle well. Apple stopped being used for saw handles when Disston had to switch to beech for most saws in the 1940's. A supply of quality applewood, suitable for mass production, didn't exist after World War II. | |

| |

|

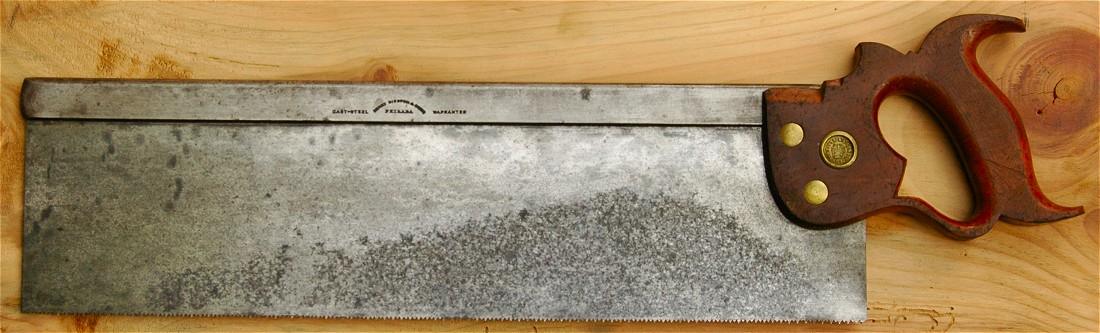

This 18" Disston No. 4 backsaw from the late 1870's is similar to the saw on which the Bad Axe tenon saw is modeled.

When the two saws are together, you can see the influence of the Disston saw. The quality of the materials and workmanship on the Bad Axe saw is excellent. This is a saw that looks, feels, and cuts like a new 19th century saw did. Bad Axe Tool Works has put a lot of effort into making a saw with traditional features that are like no one else's on the market. The result is a saw that both appears and functions like a saw that Henry Disston would have put his own name on.

Erik von Sneidern |